Belgunderground

Mitglied

- Beiträge

- 9

Gerne  mal sehen was wir hin kriegen.

mal sehen was wir hin kriegen.

Folge dem Video unten, um zu sehen, wie du das Forum als Web-App installieren kannst.

Anmerkung: Dies funktioniert aktuell nur über den Safari Browser.

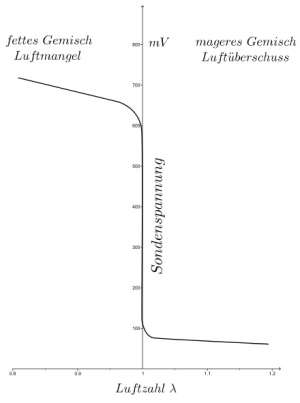

The o2 Sensor kan only read Stochiometric 14.6 AFR and is used as a switch at that point between rich and lean. :/ a wideband can measure the AFR specifically

Hey

Die meisten Fahrzeuge verwenden einen Sauerstoffsensor. (o2 sensor/narrowband)

Diese sind heute mit Heizung, daher 4 kabeln. (2x heating 1x ground 1x signal)

Die alten haben nu 2 kabeln, signal & ground.

Wideband sensor haben 6 kabeln.

Der Zweck dieser Sonde ist es, eine reine Verbrennung zu gewährleisten, die Lambda 1 entspricht. ...

Es ist aber doch möglich den ecu zu optimieren. Gerne sende mir einen bin.fil und 4 guten datalog.

@Der RaucherThe o2 Sensor kan only read Stochiometric 14.6 AFR and is used as a switch at that point between rich and lean. :/ a wideband can measure the AFR specifically

I do understand your couriosity, and i can tell you what i figured out the past 3 years street tuning my bike. (yingang yg125-23a).

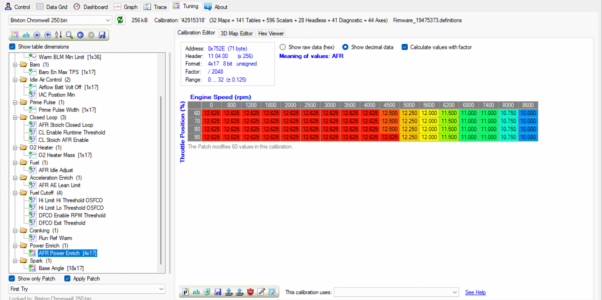

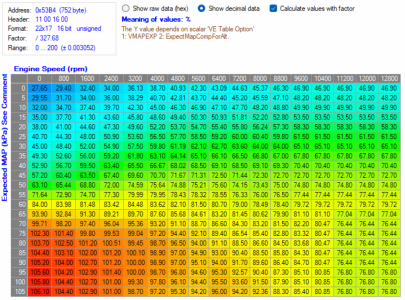

The bikes VE map, is whats all about. And the map is a combination between your question, and the fact of the narrowband usage.

Stochiometric is not the problem in theorie. That is an easy closed loop (hence the name) . But why is it possible to "adjust" the closed loop stochiometric setting.When your are in closed loop, the ECu will take the startpoint by the VE table, and correct into stochio when driving around. So the VE table will be able to work under most conditions worldwide, because it will be compensated by the oxygen sensor.

The Ecu does not know more, then what is programmed in advance.

So when you are going into power enrichment mode, it brakes out of the Closed loop, and is then ONLY using the VE table, and the enrichment calculatet by the value given in the ECU.

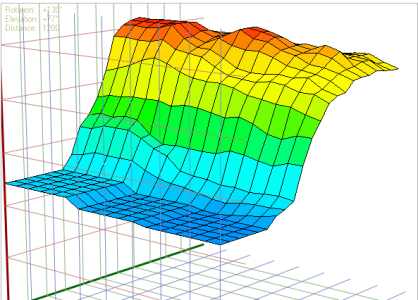

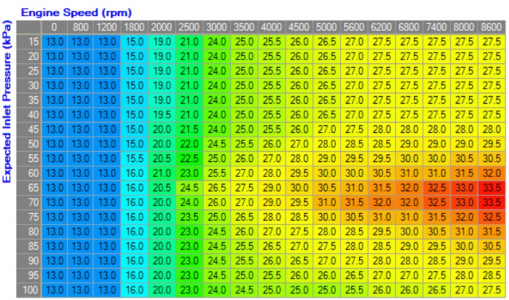

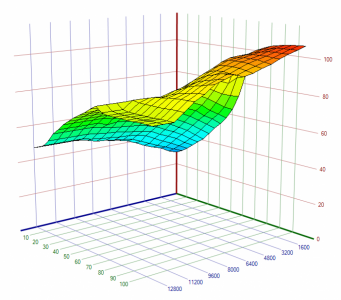

look a my original shitty VE:

Anhang anzeigen 25472

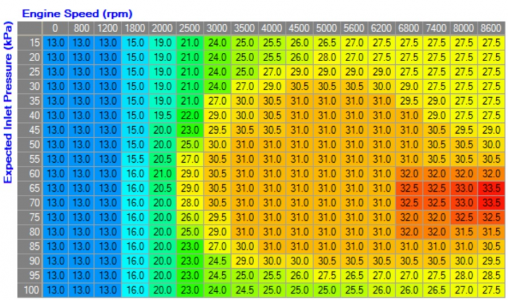

And now:

Anhang anzeigen 25473

So, what i believe is, that your whole map of your bike.... probably is as shitty as mine was !

And surely, your injector is to short.

Actually my project is already on the limit of what is possible as my clutch starts to slip. I had to dial back my settings to catch the clutch again. I know that the engine could do more but I can not get that power on the weel!If you want, i would like this project and in return you can get a taste of what could be possible. The cost is your time, and driving around until we get a base map to work on.

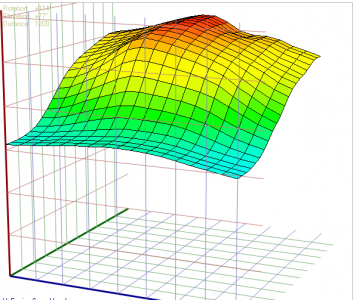

Ve map is the volumetric efficiency map of your engine wich works like an airpump. Airflow > Ve Main 1. it shows the efficiency of the engine through RPM and load and is used as base for other calculations inside the ecu. An a 3 D view give a more holistic view of the performance curve of the engine. in 2 D it would look like a torque curve.What exactly is the "VE" map?

Since the AFR is different between fuels, you need to tell it at what point lambda is for the specific fuel since lambda is defined as AFR in the ECU. If you drive with E10 you should adjust it to it, or else you risk driving in lean condition, wich gives more heat, wear , and higher risk for knock, especially when you have modified the ignition angel.But why is it possible to "adjust" the closed loop stochiometric setting.

It is correct that ignition angel is the key for producing power, but also more risky if there is no knock detector, and the VE table is not right.I had much more success with the ingnition angle:

No. I mean the injector duty cycle, wich is the size/amount of fuel at given pressure that can be injected without going static (open all the time) it should be at 85% max. a OBD reader can calculate the duty cycle/injector load.Could you be more specific? Are you talking about injection time?

when are you intending to change the clutch plates?Actually my project is already on the limit of what is possible as my clutch starts to slip.

OK, got it.Ve map is the volumetric efficiency map of your engine wich works like an airpump. Airflow > Ve Main 1. it shows the efficiency of the engine through RPM and load and is used as base for other calculations inside the ecu. An a 3 D view give a more holistic view of the performance curve of the engine. in 2 D it would look like a torque curve.

Since the AFR is different between fuels, you need to tell it at what point lambda is for the specific fuel since lambda is defined as AFR in the ECU.

If you drive with E10 you should adjust it to it, or else you risk driving in lean condition, wich gives more heat, wear , and higher risk for knock, especially when you have modified the ignition angel.

It is correct that ignition angel is the key for producing power, but also more risky if there is no knock detector,

and the VE table is not right.

How do you know, that the changes do not affect the vitality of the engine under given RPM and loads? Unlike the VE, you can not calculate when knock occurs, but you can measure when you are driving lean.

No. I mean the injector duty cycle, wich is the size/amount of fuel at given pressure that can be injected without going static (open all the time) it should be at 85% max. a OBD reader can calculate the duty cycle/injector load.

when are you intending to change the clutch plates?

On the other side, dataprocessing takes time, and if you gather enough data for me to process, i could make a base file out of it for when you have changed the plates.

The only remaining goal is, to make it as efficient as possible without losing the power/tourque level I already have.

the Engine is slowed down at 10000 at other points in the ECU and can not overcome 8500 in real life ...

Duty cucle is calculated value between injector pulse width and RPM, even when static it can be programmed in the ecu to reduce performance by adding enrichment. like the AFR of 10 addet enrichment airflow by 0.934(fx) wich results on massive enrichment and reducing performance and or cooling as well as reducing ingition angel. When Pe mode acitvated it while augment the enrichment further when entering extended PE mode.I could not measure it but think that the ECU is adjusting the duty cycle to that because I do not get excessive heat

I like that you changed to EDC, waiting for my brakes from them. i did keep my oil 15w-40 synthetic MA2 and i did add some X1-R with great results.I changed the no name plates to "EDC heavy dutty" plates, swapped to stronger springs and replaced the 10W40 to 5W50 (thicker at heat). Without this it would be much worse.

If you would like it to find it yourself, i do respect that and wishing all good an that. What i can not figure out, is why not take the possibility of the help that i am offering? There is no cost for you or for me, and neither is it bothering for any of us. furthermore, you want to find the most efficiency and i want to calculate it, so this offer is straight forward.The VE map might be helpfull in that task and I want to "find" the best setting by myself

Dito! I alearned a lotThanks for your response. I am enjoying the conversation

What i do not understand, is your relation to efficiency

From my point of view, efficiency is a relation between performance and consumption, do you want more efficiency ...

Again, you are absolutly right - in theorie! I just can not utilieze a "higher" performanceOne essentiel factor is, fuel injector size: you need to secure fuel throughout the RPM and loads, the original is not capable of that, unless the data shows something else. Uselly i smaller injector is placed as a restrictor, if no more fuel can be added, you can not get higher performance in given situations.

This would mean it runs to hot - checked and it doesntBut also more factors come into considerations, like leaning out,

At certain points in the cylinder because of combustion. It runs for more then y year or about 5000km. Of course I can not be sure but I think I am fine here too.heat accumulation,

Not an issue. I cant prove that as I do not have a knocking sensor but as I know that other similar engines have a much higher compression - and I trust to be able to hear excessive knoking (as I recognized it in the past, years ago, on a car with carburator).predetonations.

I havent felt it, thats true, but I could definately hears it.You do not hear knock/predetonation while driving as exemple, and mostly, you do not even feel it.

Yes, getting real data is always better than just have the "feeling" or an indirect confirmation (which I have both)So what regards knock, i keep in mind, that this is an assumption and i prefere data for validation.

I like that you changed to EDC, waiting for my brakes from them. i did keep my oil 15w-40 synthetic MA2 and i did add some X1-R with great results.

If you would like it to find it yourself, i do respect that and wishing all good an that. What i can not figure out, is why not take the possibility of the help that i am offering? There is no cost for you or for me, and neither is it bothering for any of us. furthermore, you want to find the most efficiency and i want to calculate it, so this offer is straight forward.

But that wonder asside, for anyone reading this wich could be interessted in a map. Pm me. Like I stated before, a .bin file and some logging is all i need for working on a new projekt.

Nein im Gegenteil.Offensichtlich etwas Missfallen ob der Englischen Sprache, insbesondere bei meiner dahingeholperten Ausdrucksweise - oder ist es gerade deswegen? Sehr interessant so was im Jahr 2023 noch zu erleben ...

until then, as respons to your answer, your are right, we do mostly only have 1 bikeSchalten Sie auch in zwei Wochen wieder ein, zu einer weiteren Folge:

Mit dem Bin.file aus der 5.03 kann ich leider nicht dienen. Der lässt sich mit ECU Hacker 4.9 noch nicht auslesen. Habe heute mal ein Paar Logs erstellt. dazu hast Du ne PN.Wurde gerne helfen mit den Tuning

Brauche den Bin.file und 4 gute und indholdsreiche datalogs.

Ergänzung ()

Du kanst einfach die mt5.3 datalogen und die VEmap in einen mt05.2 überfuhren. ? Du kannst mir ja mal ein paar Logs senden?